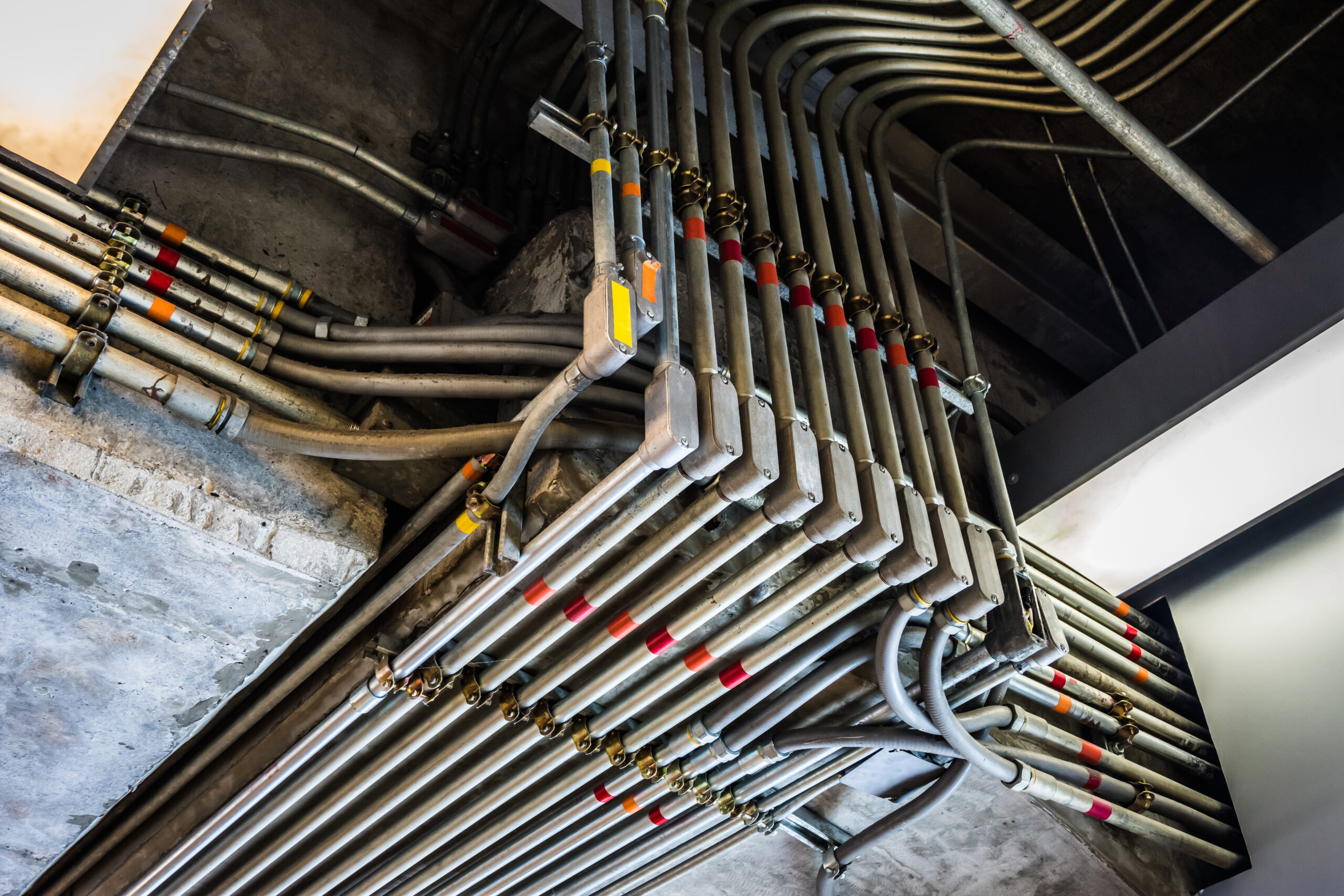

Induction welding equipment

Our cutting-edge High-Frequency Induction Brazing Equipment revolutionizes pipeline welding in the refrigeration industry, offering advanced, high-frequency welding solutions. Specializing in efficiency and safety, our equipment is pivotal for OEMs producing durable, high-quality welds in home appliances, electronics, and a wide range of other industries.

With the introduction of high-frequency induction brazing equipment, we have initiated a green revolution in pipeline welding within the refrigeration industry.

Features

- Green Technology: The equipment replaces traditional flame welding, contributing to a more environmentally friendly and sustainable manufacturing process.

- High Efficiency: High-frequency induction brazing enables rapid heating and welding, significantly improving production efficiency for OEMs.

- Superior Weld Quality: The process results in durable, high-quality welds that are essential for the reliability and longevity of products in various industries.

- Versatility: Tungray’s equipment caters to diverse industries, including home appliances, automotive, electronics, energy, and more, showcasing its adaptability to various applications.

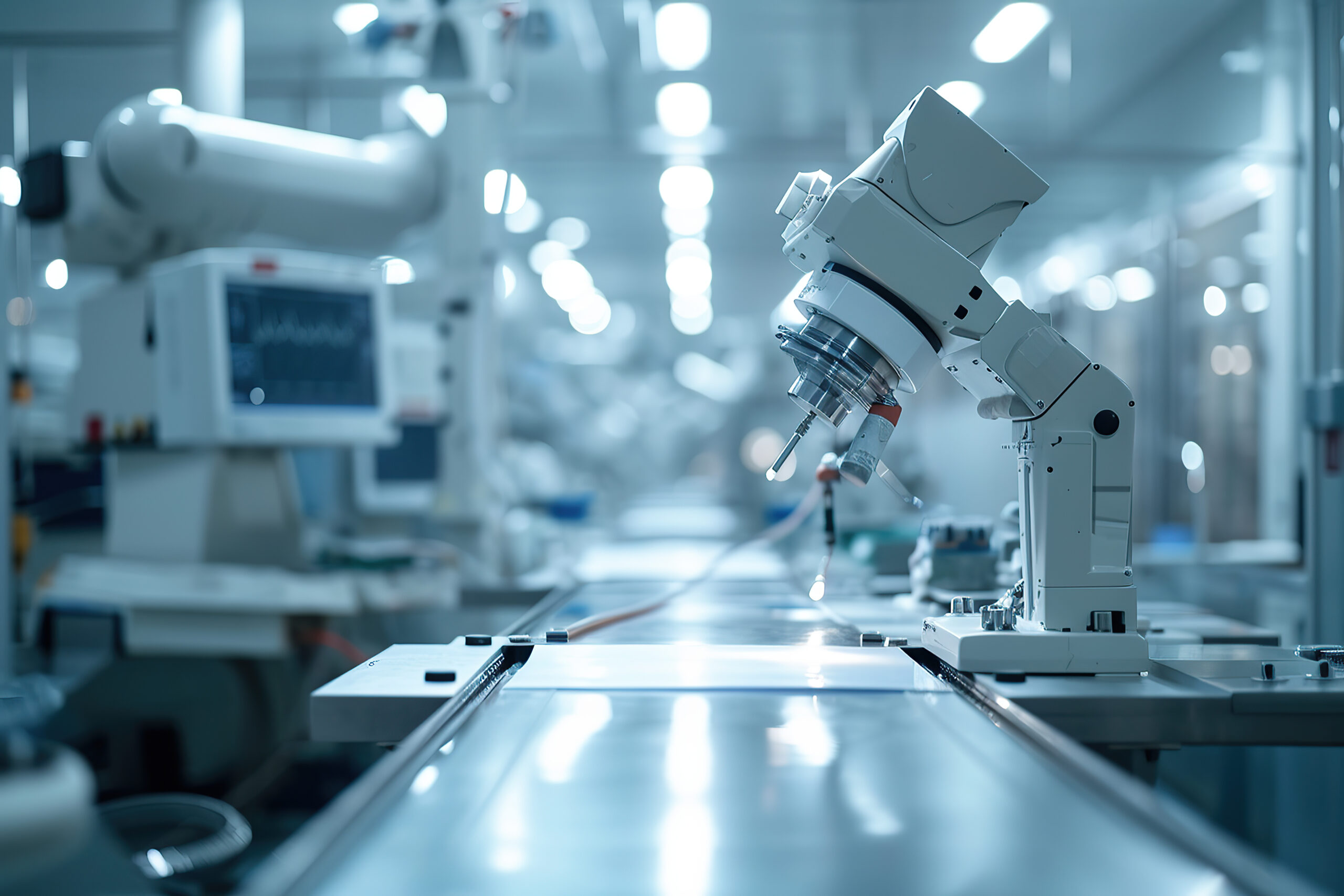

- Automation and Precision: The integration of robotics and vision automation allows for precise and consistent welding, reducing errors and improving overall product quality.

- Customization: Tungray offers specialized induction brazing equipment and solution-based assembly systems tailored to the specific needs of clients, ensuring optimal performance and integration with existing production lines.

- Innovation: The company actively develops and iteratively improves its product lines, including induction coil welding heads for various applications and materials, staying at the forefront of technological advancements.

Major industries we support

Contact us

Contact a member of our team